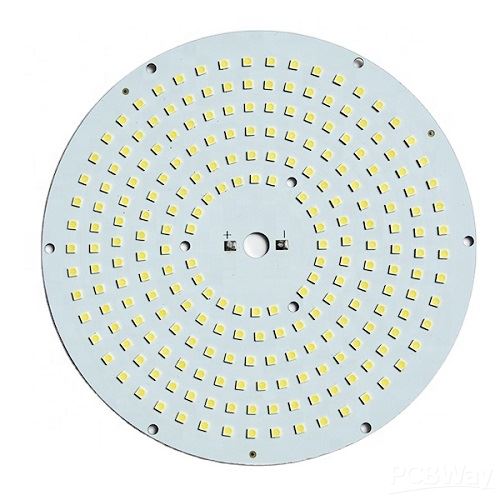

LED lighting is a rapidly growing industry that provides an energy-efficient and cost-effective alternative to traditional incandescent and fluorescent lighting solutions. At CEN PCBA, we specialize in high-quality PCB assembly services across various industries, with extensive experience in PCB fabrication and assembly for LED lighting applications. While LED PCB assembly may seem straightforward, these projects come with unique challenges that require specialized expertise.

Critical aspects

One of the most critical aspects of LED PCBs is thermal management. Although LED lighting is known for its low power consumption and reduced heat output compared to conventional lighting, LEDs still generate a significant amount of heat. Proper heat dissipation is crucial to maintaining performance and longevity, making PCB material selection a key consideration in LED applications.

ED PCB designs

For LED PCB designs, choosing the right base material is essential. At CEN PCBA, we offer a range of high-temperature PCB materials, including standard FR-4 substrates with high glass transition temperature (Tg) values to withstand the reflow soldering process. However, for projects requiring superior thermal conductivity, we provide metal-core PCBs (MCPCBs). These MCPCBs offer through-plane thermal conductivity of 1.0 to 3.0 W/m∙K, significantly enhancing heat dissipation compared to standard FR-4 materials.

While metal-core PCBs provide excellent thermal performance, they come at a slightly higher cost. To ensure the best solution for your project, we recommend ordering a small batch of both FR-4 and MCPCB versions for testing before full-scale production.

With years of experience in PCB manufacturing and assembly, CEN PCBA is your trusted partner for LED PCB projects. If you have any inquiries or need assistance with your design, contact us today to get started